You Are Here:Home > Information dynamic

> Company Dynamics

News Navigation

Which is better, particle board or density board

source:English website Time:2022-07-22

MDF, also known as MDF, is an artificial board made of wood fibers or other plant fibers, which is crushed, separated and dried, then applied with urea formaldehyde resin or other applicable adhesives, and then hot pressed.

The advantage is that the material is fine, and the cutting surface will be sealed well when sealing the edge, so it is not easy to open the glue. It is easy to press into various shapes, and it is easy to make shapes, so there are usually more door panels or backboards.

Disadvantages: because the base material is powder, it uses more glue than particle board, which is more likely to cause environmental problems. Secondly, due to the high glue content of the density board, less internal structure space and poor moisture resistance, soak a piece of density board in water for 24 hours, and it is obvious that the four sides of the density board are warped and deformed after more than ten hours.

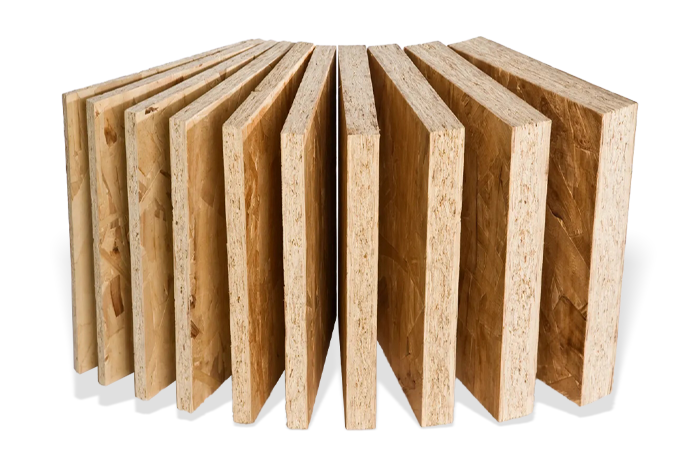

Solid wood particle board is a man-made board made of wood or other lignocellulose materials, which is glued under the action of heat and pressure after applying adhesive. The principle is the same as that of density board.

The advantages are: 1. The interior of solid wood particle board is granular with cross staggered structure. Therefore, the nail holding force is good, and round nails and screws can be nailed. These machinability properties are obviously better than density board. 2. The density of solid wood particle board is higher, and the wood fiber particles in the board are larger, which retains the essence of natural wood. In the use of adhesives, the content of solid wood particle board is generally less than 5%, and the environmental protection is better. 3. Solid wood particle board has small warpage and deformation, stable size, high strength and stiffness, and it is not easy to bend when hanging heavy clothes. At present, the wood-based panel used in the European furniture market is mainly solid wood particle board.

The disadvantage is that the flatness of solid wood particle board is not as good as that of density board, and it is difficult to make radian and shape.

At present, in the European market, for the sake of environmental protection, solid wood particle board is basically the main one, while most domestic manufacturers also use solid wood particle board as the cabinet substrate. In fact, it is better to use both in a wardrobe. Therefore, the safety net recommends that you use density board for the back plate and solid wood particle board for the laminate. This can not only take advantage of the good flatness of density board, but also make the product shape more beautiful. At the same time, it also takes advantage of the environmental protection of solid wood particle board, which can create an environmental friendly living environment to a great extent.

The advantage is that the material is fine, and the cutting surface will be sealed well when sealing the edge, so it is not easy to open the glue. It is easy to press into various shapes, and it is easy to make shapes, so there are usually more door panels or backboards.

Disadvantages: because the base material is powder, it uses more glue than particle board, which is more likely to cause environmental problems. Secondly, due to the high glue content of the density board, less internal structure space and poor moisture resistance, soak a piece of density board in water for 24 hours, and it is obvious that the four sides of the density board are warped and deformed after more than ten hours.

Solid wood particle board is a man-made board made of wood or other lignocellulose materials, which is glued under the action of heat and pressure after applying adhesive. The principle is the same as that of density board.

The advantages are: 1. The interior of solid wood particle board is granular with cross staggered structure. Therefore, the nail holding force is good, and round nails and screws can be nailed. These machinability properties are obviously better than density board. 2. The density of solid wood particle board is higher, and the wood fiber particles in the board are larger, which retains the essence of natural wood. In the use of adhesives, the content of solid wood particle board is generally less than 5%, and the environmental protection is better. 3. Solid wood particle board has small warpage and deformation, stable size, high strength and stiffness, and it is not easy to bend when hanging heavy clothes. At present, the wood-based panel used in the European furniture market is mainly solid wood particle board.

The disadvantage is that the flatness of solid wood particle board is not as good as that of density board, and it is difficult to make radian and shape.

At present, in the European market, for the sake of environmental protection, solid wood particle board is basically the main one, while most domestic manufacturers also use solid wood particle board as the cabinet substrate. In fact, it is better to use both in a wardrobe. Therefore, the safety net recommends that you use density board for the back plate and solid wood particle board for the laminate. This can not only take advantage of the good flatness of density board, but also make the product shape more beautiful. At the same time, it also takes advantage of the environmental protection of solid wood particle board, which can create an environmental friendly living environment to a great extent.

Previous:

Differences and characteristics between particleb…

Next:

What are the advantages of solid wood particle bo…

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell