You Are Here:Home > Information dynamic

> Company Dynamics

News Navigation

What are the advantages of solid wood particle board

source:English website Time:2022-07-22

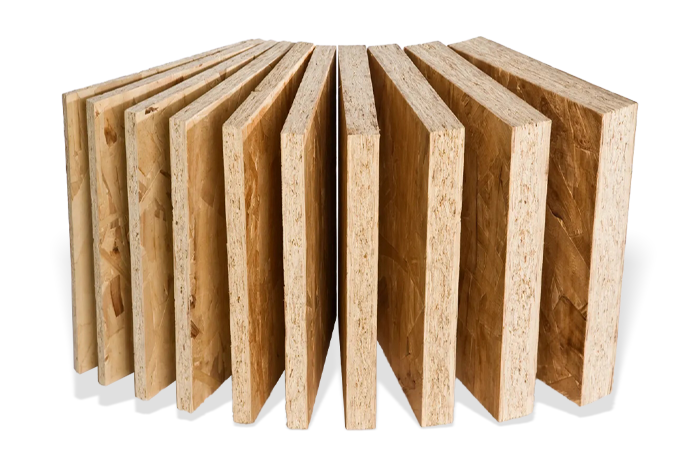

In the domestic panel furniture industry, solid wood particle board (a kind of particleboard) or medium fiber board (a kind of density board) is mostly used. In some panel furniture, some base materials use solid wood particle board, and some base materials use density board. What are the advantages of solid wood particle board?

Excellent environmental protection performance: the density of solid wood particle board is higher, and the wood fiber particles in the board are larger, which retains the essence of natural wood more. In the use of adhesives, the content of solid wood particle board is generally less than 5%, and the environmental protection is better.

Decorative performance is relatively strong: solid wood particle board is a board made of wood chips as raw materials, taking certain physical and chemical essentials to participate in the processing of adhesives or other additives. Compared with natural firewood, it has wide board surface, smooth and greasy appearance, no knots, wormholes, anisotropy and other shortcomings, no warping, no cracking, high physical and mechanical strength, equal longitudinal and transverse strength, sound insulation, mildew prevention, economy, heat preservation, etc.

Warpage is not easy to deform: solid wood particle board has small warpage and deformation, good dimensional stability, high strength, good stiffness, and it is not easy to bend when hanging heavy clothes. Wood based panels used in the European furniture market are mainly solid wood particle panels.

Strong nail holding force: the interior of solid wood particle board is in the shape of particles with cross and staggered structure. Therefore, the nail holding force is good, and round nails and screws can be nailed. These machinability properties are obviously better than density board.

Good processing performance: the density of solid wood particle board is generally greater than that of solid wood, and its physical and mechanical properties are good. Among all kinds of wood-based panels, it is closest to natural firewood and better than natural firewood. Therefore, the machine has excellent processing performance, which can be processed with the processing configuration and essentials of processing natural firewood. The interior of solid wood particle board is in the form of particles with cross and staggered layout. The particles are arranged in a certain direction, and its longitudinal bending strength is much greater than that of the transverse. It can be sawed, sanded, planed, drilled, nailed, filed and other processing. It is a good material in the furniture industry.

Excellent environmental protection performance: the density of solid wood particle board is higher, and the wood fiber particles in the board are larger, which retains the essence of natural wood more. In the use of adhesives, the content of solid wood particle board is generally less than 5%, and the environmental protection is better.

Decorative performance is relatively strong: solid wood particle board is a board made of wood chips as raw materials, taking certain physical and chemical essentials to participate in the processing of adhesives or other additives. Compared with natural firewood, it has wide board surface, smooth and greasy appearance, no knots, wormholes, anisotropy and other shortcomings, no warping, no cracking, high physical and mechanical strength, equal longitudinal and transverse strength, sound insulation, mildew prevention, economy, heat preservation, etc.

Warpage is not easy to deform: solid wood particle board has small warpage and deformation, good dimensional stability, high strength, good stiffness, and it is not easy to bend when hanging heavy clothes. Wood based panels used in the European furniture market are mainly solid wood particle panels.

Strong nail holding force: the interior of solid wood particle board is in the shape of particles with cross and staggered structure. Therefore, the nail holding force is good, and round nails and screws can be nailed. These machinability properties are obviously better than density board.

Good processing performance: the density of solid wood particle board is generally greater than that of solid wood, and its physical and mechanical properties are good. Among all kinds of wood-based panels, it is closest to natural firewood and better than natural firewood. Therefore, the machine has excellent processing performance, which can be processed with the processing configuration and essentials of processing natural firewood. The interior of solid wood particle board is in the form of particles with cross and staggered layout. The particles are arranged in a certain direction, and its longitudinal bending strength is much greater than that of the transverse. It can be sawed, sanded, planed, drilled, nailed, filed and other processing. It is a good material in the furniture industry.

Previous:

Which is better, particle board or density board

Next:

none

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell