You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

Differences and characteristics between particleboard and density board

source:English website Time:2022-07-22

In the process of decoration, board is a common building material. There are many kinds of board, including particleboard, MDF, plywood, fireproof board and gypsum board. But today, Jiangsu New Oriental wood based panel Co., Ltd. wants to introduce the difference between particleboard and MDF. What is the difference between particleboard and MDF? Come and have a look.

Nowadays, particleboard and density board are in the majority in the building materials industry in the market. Many people sometimes can't distinguish these two kinds of boards. In fact, these two kinds of boards are still very different in essence. Particleboard, also known as particle board, is a man-made board made of crushed materials after processing, so it can also be called particleboard. Particleboard is mainly used in furniture manufacturing and construction industry because of its uniform capacity, pollution resistance, aging resistance and beautiful appearance. Density board, also known as fiberboard. The artificial board made of wood fiber or other plant fiber and applied with urea formaldehyde resin or other applicable adhesives can be divided into high-density board, medium density board and low-density board according to their density. Due to its soft quality and impact resistance, MDF is also easy to reprocess. In foreign countries, density board is more suitable for making furniture, but because China's standard for height board is several times lower than the international standard, the use quality of density board in China needs to be improved.

Difference between particleboard and density board

In real life, particleboard and density board are often confused. They are both made of wood and fiberwood. The main differences are as follows:

1. Different manufacturing processes

Particleboard is a kind of artificial board made of wood or other wood and fiber materials, which is glued under the action of pressure and heat; Density board is made of wood and fiber materials by crushing and pressing them into water and then using adhesives.

2. Different appearance

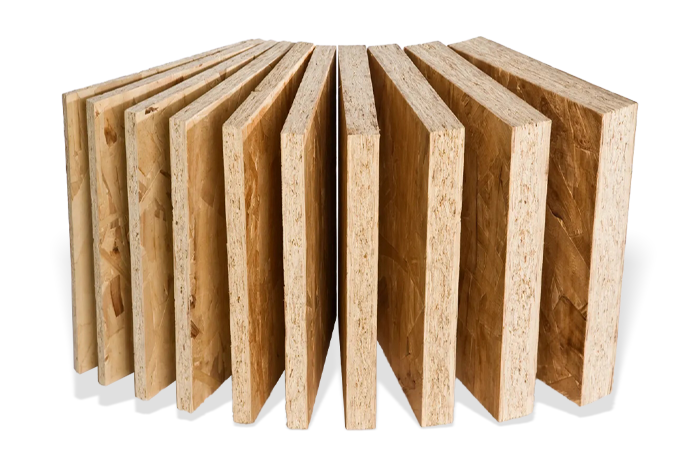

The material cross section of particleboard is three layers, the outer two layers are fine particles, and the particles in the middle layer are larger; Density board is also called fiberboard. Its cross-section has the same color and particle size distribution.

3. Different characteristics

Density board is formed by pressing wood powder, and the surface flatness is good. Therefore, when the surface needs to be milled and formed, and the bonding surface is soft (such as carved blister board), medium density board is often used to ensure the surface smoothness after coating. However, since all the raw materials are very fine wood powder, from the perspective of moisture resistance, if the particleboard is soaked in water, because there are long wooden fibers in the particleboard, more of the wood structure is retained, so the particleboard will not expand to a certain extent (8% - 10%). Therefore, the comprehensive moisture-proof performance of particleboard is better than that of density board. The density board is composed of powder, which is easy to expand in case of water. Therefore, it can't be used as a box, and because of its poor nail eating ability, generally speaking, the density board nail is hit to the surface and then taken out. In this way, it can't be used after five times. However, particleboard is made of wood chips, which are pressed into boards. It has the characteristics of wood and has a certain nail holding force. Generally, it can be repeated about 10 times.

The above is the relevant introduction about "the difference between particleboard and density board" brought by Jiangsu New Oriental wood based panel Co., Ltd. to friends. From this, we can see that the difference between particleboard and density board exists in all aspects. Therefore, whether to buy particleboard and density board can be decided according to their actual needs.

Nowadays, particleboard and density board are in the majority in the building materials industry in the market. Many people sometimes can't distinguish these two kinds of boards. In fact, these two kinds of boards are still very different in essence. Particleboard, also known as particle board, is a man-made board made of crushed materials after processing, so it can also be called particleboard. Particleboard is mainly used in furniture manufacturing and construction industry because of its uniform capacity, pollution resistance, aging resistance and beautiful appearance. Density board, also known as fiberboard. The artificial board made of wood fiber or other plant fiber and applied with urea formaldehyde resin or other applicable adhesives can be divided into high-density board, medium density board and low-density board according to their density. Due to its soft quality and impact resistance, MDF is also easy to reprocess. In foreign countries, density board is more suitable for making furniture, but because China's standard for height board is several times lower than the international standard, the use quality of density board in China needs to be improved.

Difference between particleboard and density board

In real life, particleboard and density board are often confused. They are both made of wood and fiberwood. The main differences are as follows:

1. Different manufacturing processes

Particleboard is a kind of artificial board made of wood or other wood and fiber materials, which is glued under the action of pressure and heat; Density board is made of wood and fiber materials by crushing and pressing them into water and then using adhesives.

2. Different appearance

The material cross section of particleboard is three layers, the outer two layers are fine particles, and the particles in the middle layer are larger; Density board is also called fiberboard. Its cross-section has the same color and particle size distribution.

3. Different characteristics

Density board is formed by pressing wood powder, and the surface flatness is good. Therefore, when the surface needs to be milled and formed, and the bonding surface is soft (such as carved blister board), medium density board is often used to ensure the surface smoothness after coating. However, since all the raw materials are very fine wood powder, from the perspective of moisture resistance, if the particleboard is soaked in water, because there are long wooden fibers in the particleboard, more of the wood structure is retained, so the particleboard will not expand to a certain extent (8% - 10%). Therefore, the comprehensive moisture-proof performance of particleboard is better than that of density board. The density board is composed of powder, which is easy to expand in case of water. Therefore, it can't be used as a box, and because of its poor nail eating ability, generally speaking, the density board nail is hit to the surface and then taken out. In this way, it can't be used after five times. However, particleboard is made of wood chips, which are pressed into boards. It has the characteristics of wood and has a certain nail holding force. Generally, it can be repeated about 10 times.

The above is the relevant introduction about "the difference between particleboard and density board" brought by Jiangsu New Oriental wood based panel Co., Ltd. to friends. From this, we can see that the difference between particleboard and density board exists in all aspects. Therefore, whether to buy particleboard and density board can be decided according to their actual needs.

Previous:

Do you know how long it takes for formaldehyde in…

Next:

Which is better, particle board or density board

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell