You Are Here:Home > Information dynamic

> Industry Trends

News Navigation

What are the characteristics of odorless E0 grade environmentally friendly particleboard

source:www.wzvpn.cn Time:2024-10-29

Odorless E0 grade environmentally friendly particleboard has the following characteristics:

1. Excellent environmental performance:

The formaldehyde emission is relatively low: E0 level is a higher environmental standard level, with a formaldehyde emission of ≤ 0.050mg/m 3 (new national standard) or ≤ 0.5mg/L (some standards), which means that it has very little impact on indoor air quality and is suitable for places with high environmental requirements, such as children's rooms, bedrooms, hospitals, etc.

Raw material environmental protection: It is mainly processed from crushed wood or other wood cellulose materials. If the wood used comes from sustainably managed forests, it can further reduce its impact on the environment. And in the production process, the use of harmful substances is minimized as much as possible to ensure the environmental friendliness of the board.

2. Good physical performance:

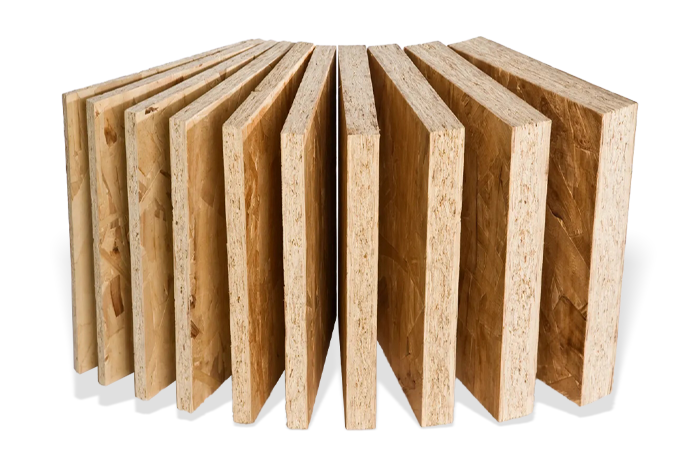

High strength: After reasonable hot pressing process and structural design, the particle structure inside the particleboard presents a cross staggered pattern, which gives it good static bending strength and bending resistance, and can withstand certain pressure and weight. It can be used to make furniture, cabinets, flooring and other products that require strength.

Good dimensional stability: The expansion coefficient of the board is small, and the dimensional changes are small under different temperature and humidity conditions, making it less prone to deformation, cracking, and other problems, ensuring the long-term performance of the product.

Sound and heat insulation: The particle structure and pores inside the particleboard can effectively block the propagation of sound and heat transfer, and have good sound and heat insulation effects. It can be used for building walls, partitions, and other parts to improve indoor comfort.

3. Good processing performance:

Easy to cut: The texture of the board is relatively uniform, and ordinary woodworking tools can be used for cutting, sawing and other processing operations, which can meet the processing needs of various shapes and sizes, and facilitate the production of different styles of furniture and decorations.

Can be veneered: Its surface is flat and suitable for pasting various veneer materials, such as melamine impregnated paper, wood veneer, PVC, etc., which can achieve rich surface decorative effects and meet different design styles and aesthetic needs.

4. Relatively low cost: Compared with other boards such as solid wood and multi-layer boards, the production process of particleboard is relatively simple, and the utilization rate of raw materials is high. Therefore, the cost is relatively low, and it has a high cost-effectiveness, which can provide consumers with an affordable choice.

5. High resource utilization rate: During the production process of particleboard, wood processing residues, small-diameter wood and other resources can be fully utilized, which improves the comprehensive utilization rate of wood and reduces wood waste, in line with the concept of sustainable development.

1. Excellent environmental performance:

The formaldehyde emission is relatively low: E0 level is a higher environmental standard level, with a formaldehyde emission of ≤ 0.050mg/m 3 (new national standard) or ≤ 0.5mg/L (some standards), which means that it has very little impact on indoor air quality and is suitable for places with high environmental requirements, such as children's rooms, bedrooms, hospitals, etc.

Raw material environmental protection: It is mainly processed from crushed wood or other wood cellulose materials. If the wood used comes from sustainably managed forests, it can further reduce its impact on the environment. And in the production process, the use of harmful substances is minimized as much as possible to ensure the environmental friendliness of the board.

2. Good physical performance:

High strength: After reasonable hot pressing process and structural design, the particle structure inside the particleboard presents a cross staggered pattern, which gives it good static bending strength and bending resistance, and can withstand certain pressure and weight. It can be used to make furniture, cabinets, flooring and other products that require strength.

Good dimensional stability: The expansion coefficient of the board is small, and the dimensional changes are small under different temperature and humidity conditions, making it less prone to deformation, cracking, and other problems, ensuring the long-term performance of the product.

Sound and heat insulation: The particle structure and pores inside the particleboard can effectively block the propagation of sound and heat transfer, and have good sound and heat insulation effects. It can be used for building walls, partitions, and other parts to improve indoor comfort.

3. Good processing performance:

Easy to cut: The texture of the board is relatively uniform, and ordinary woodworking tools can be used for cutting, sawing and other processing operations, which can meet the processing needs of various shapes and sizes, and facilitate the production of different styles of furniture and decorations.

Can be veneered: Its surface is flat and suitable for pasting various veneer materials, such as melamine impregnated paper, wood veneer, PVC, etc., which can achieve rich surface decorative effects and meet different design styles and aesthetic needs.

4. Relatively low cost: Compared with other boards such as solid wood and multi-layer boards, the production process of particleboard is relatively simple, and the utilization rate of raw materials is high. Therefore, the cost is relatively low, and it has a high cost-effectiveness, which can provide consumers with an affordable choice.

5. High resource utilization rate: During the production process of particleboard, wood processing residues, small-diameter wood and other resources can be fully utilized, which improves the comprehensive utilization rate of wood and reduces wood waste, in line with the concept of sustainable development.

Previous:

What are the applications of ENF board is used in…

Next:

Do you know how long it takes for formaldehyde in…

Related products

+

wechat number:底部微信

Home

Home

Wechat

Wechat

Tell

Tell